TRANSLATION OF MÖTESPLATS MODELLBYGGARE - 2001

Translation of page 1:

Guillermo Rojas Bazan

a model builder by god's grace

Rojas Bazan comes from Buenos Aires and has built models of airplanes and ships all his life. He was born in 1949 and his model building has been inherited from his father, who was a very skilled model builder himself and built model airplanes for both his son and neighboring boys. Rojas developed his technique, tried different building materials, and finally settled on aluminum as the best material. These are therefore very precise exhibition/museum models and not flying scale models.

Rojas worked at a bank until 1980. By then, the quality of his model building had reached such heights that he got a job at Argentina's Army Air Force Museum. His task was to build aluminum models of all the aircraft that appeared in the Argentine Air Force. The rumor spread and soon he was also contracted by the Argentine Navy to build models of all the planes that appeared in the fleet.

In 1988, Rojas Bazan moved to Spain to be closer to the European collector market. Through advertising in aviation magazines, the customer base gradually increased. An advertisement in the magazine Fly Past made the American Chuck Austin interested. At the same time, Rojas married Argentinian-born Clarisa and they moved to Israel where she worked as a social worker.

The Israeli Air Force then engaged Rojas to build models for the Israeli Air Force Museum. The American Austin and Rojas started an exchange as Austin wanted Rojas to come over to the United States. Rojas was interested, because he needed a new challenge that would make it fun to build again and at the same time be able to make a little more money. The family sold everything they owned and moved to Austin's hometown of New Jersey. The collaboration with Austin paid off almost immediately. Rojas was not particularly well known in the United States and his knowledge of the English language was minimal. Furthermore, they did not have work permits and could only stay as long as their tourist visas allowed.

Translation of page 2:

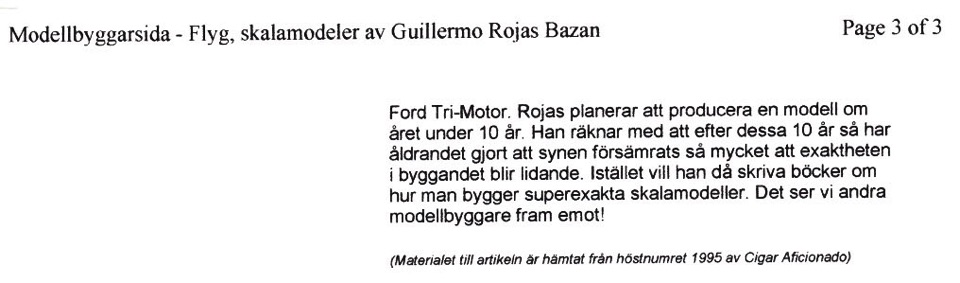

There was, however, one American who knew Rojas. His name was Gary Kohs and he owned the Fine Art Models company in Birmingham, Michigan. He made Rojas an offer that was very interesting. Gary Kohs wanted Rojas to make the most detailed 1:15 scale model aircraft ever. Gary Kohs would then have a company in Ukraine copy these down to the smallest detail and make a limited production series to sell to collectors worldwide. Kohs had previous experience with this method and had applied it to ship models, so he knew what he was getting into. Rojas Bazan and his wife moved to Michigan to start the new business.

Rojas Bazan doesn't have a nice office. He works in the family bedroom. Against one wall is a large drawing table. It is the workplace. It is so crowded that it is difficult to get past the work table to get to the beds, but it works!

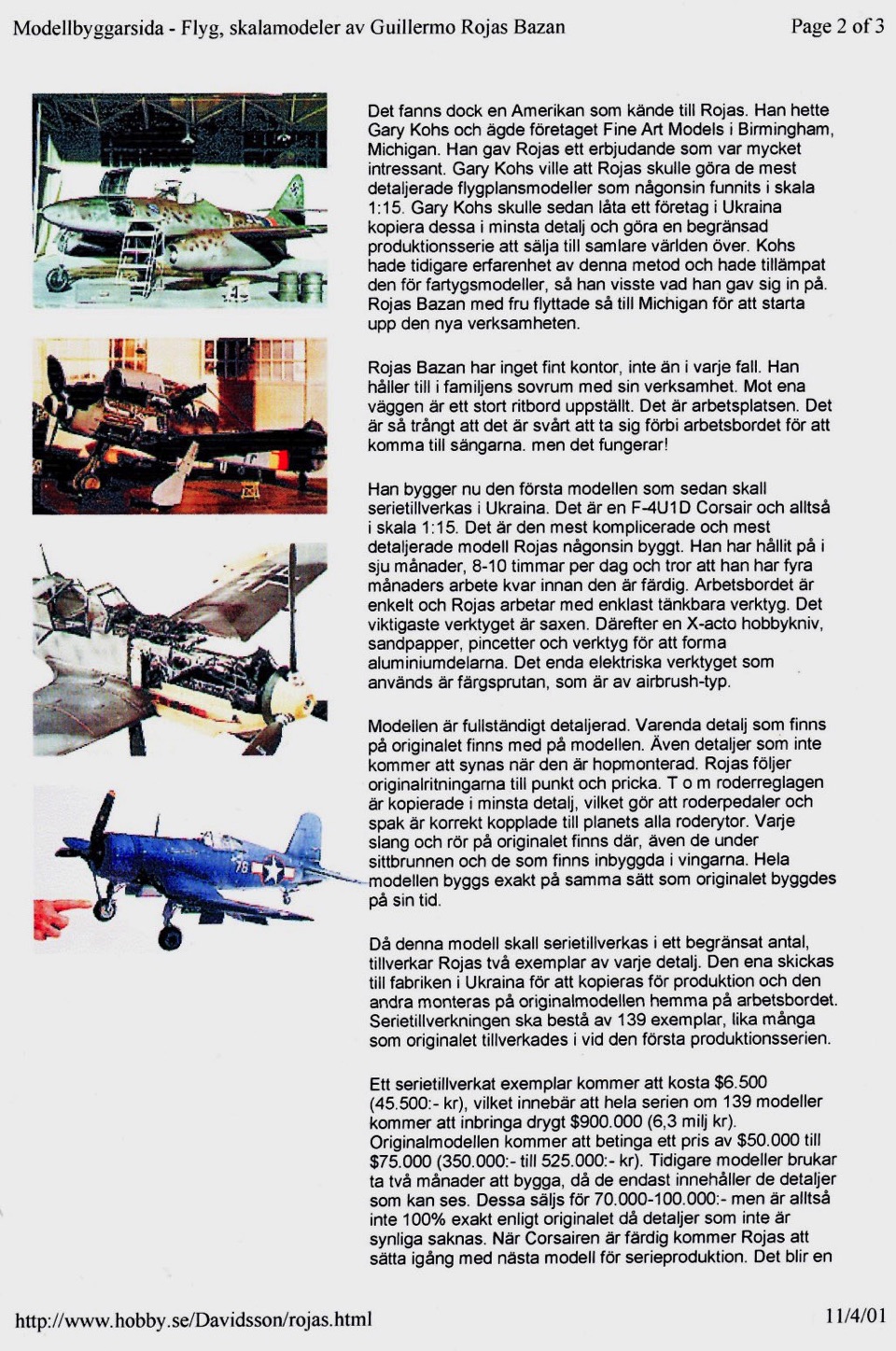

He is now building the first model which will then be serially produced in Ukraine. It's an F-4U1D Corsair, in 1:15 scale. It is the most complicated and detailed model Rojas has ever built. He has been working for seven months, 8-10 hours a day and thinks he has four months of work left before it is finished. The workbench is simple and Rojas works with the simplest imaginable tools. The most important tool are the scissors. Then an X-acto hobby knife, sandpaper, tweezers and tools to shape the aluminum parts. The only electrical tool used is the paint sprayer, which is of the airbrush type.

The model is fully detailed. Every single detail found on the original is found on the model. Even details that will not be visible when assembled. Rojas follows the original drawings to the letter. Even the rudder controls are copied in the smallest detail, which means that rudder pedals and levers are correctly connected to all rudder surfaces of the plane. Every hose and pipe on the original is there, even those under the cockpit and those built into the wings. The entire model is built exactly in the same way as the original was built in its time.

Since this model is to be serially produced in a limited number, Rojas manufactures two copies of every detali. One is sent to the factory in Ukraine to be copied for production and the other is mounted on the original model at home on the workbench. Series production will consist of 139 copies, the same number as the original was produced in the first production run. A series-produced example will cost $6,500 (SEK 45,500), which means that the entire series of 139 models will bring in just over $900,000 (SEK 6.3 million). The original model will command a price of $50,000 to $75,000 (350,000 to 525,000 SEK). Previous models usually take two months to build, as they only contain the details that can be seen. These are sold for SEK 70,000-100,000: - but are not 100% exact to the original, those details that are not visible are missing. Once the Corsair is finished, Rojas will start the next model for series production. There will be one (continues below)

Translation of page 3:

(continues from above) Ford Tri-Motor. Rojas plans to produce a model a year in the next 10 years. He reckons that after these 10 years, aging has caused eyesight to deteriorate so much that the accuracy of construction suffers. Instead, he wants to write books about how to build super-accurate scale models. We other model builders are looking forward to that!

(The material for the article is taken from the Fall 1995 issue of Cigar Aficionado)