TRANSLATION OF MODELL FAN - AUGUST 1996

Translation of cover:

Issue 8 - August 1996

MODELL FAN

International model building magazine

Translation of page 1:

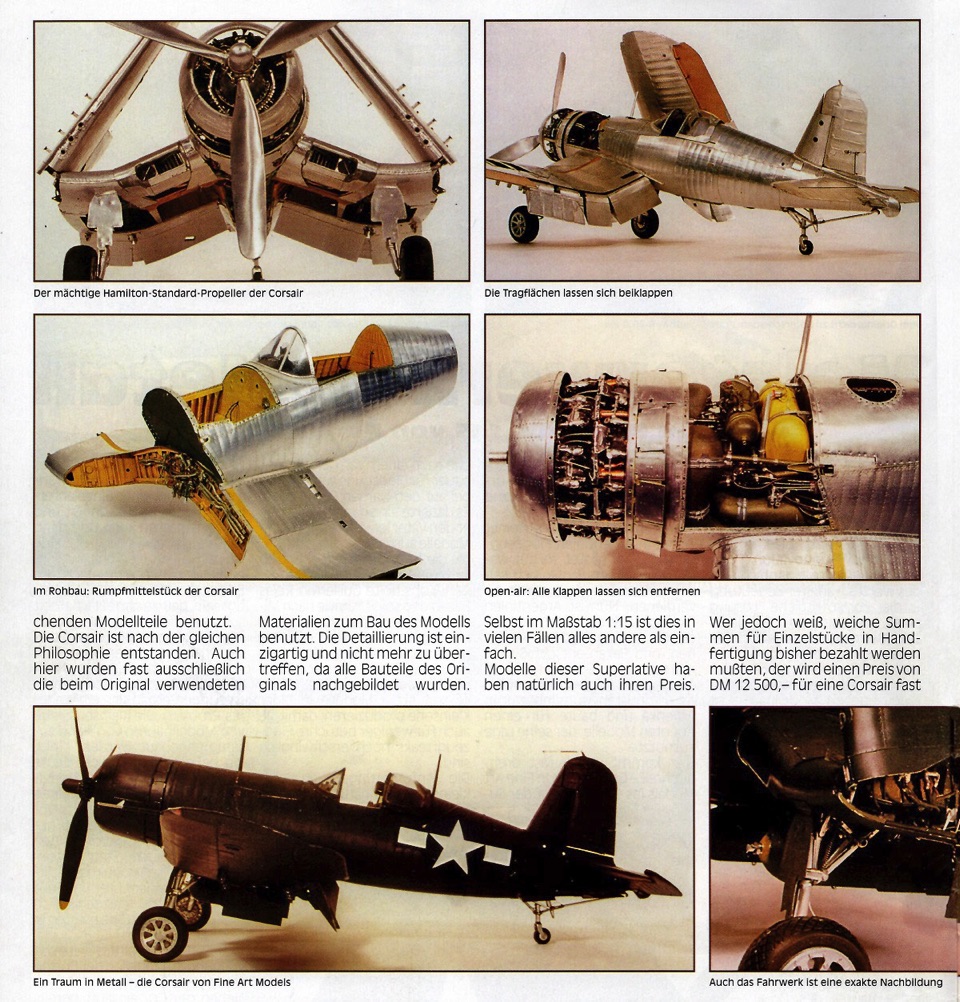

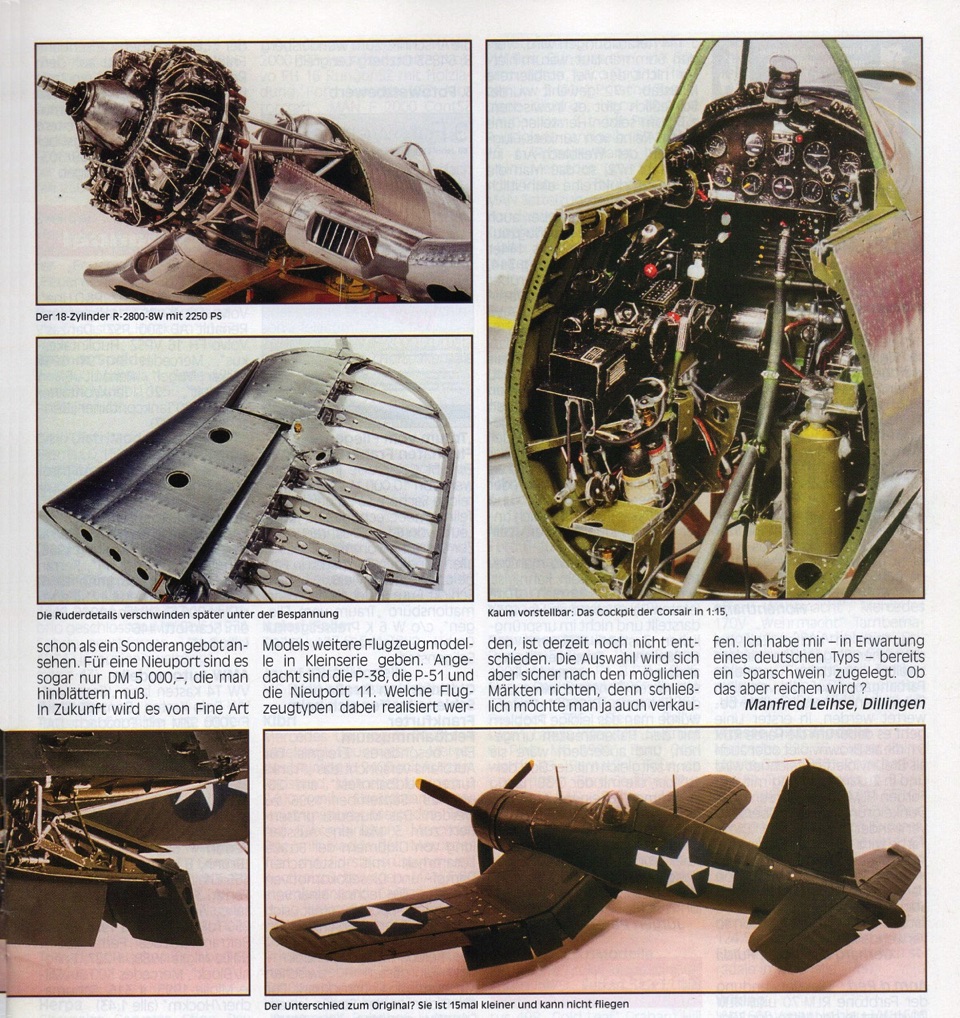

[Caption] The 18-cylinder R-2800-8W with 2250 hp

[Caption] The rudder details later disappear under the covering

[Caption] Hard to imagine: the cockpit of the Corsair in 1:15,

[Caption] The difference to the original? It is 15 times smaller and cannot fly.

(continues from above) as a special offer. For a Nieuport one only has to fork over DM 5,000. In the future, Fine Art Models will be offering further small-scale aircraft models. The P-38, the P-51 and the Nieuport 11 are being considered. It has not yet been decided which aircraft types will be realized. The selection will certainly depend on the possible markets, because after all, you want to sell. In anticipation of a German type, I have already bought a piggy bank. But will that be enough?

Manfred Leihse, Dillingen

[Caption] Indistinguishable from the original: Pratt & Whitney R-2800-8W

[Caption] Three Browning MG 53-2 in the wing of the Corsair

[Caption] F4U-1D Corsair at 1:15 scale

Masterpiece in metal

Corsair in 1:15 scale from Fine Art Models

Innovation is one of these buzzwords of our time, which can mean anything and everything, because for some people it is already innovative if you paint a wall in red instead of blue.

Innovation in model building should - in the truest sense of the word - be the advanced solution to a technical problem. However, if you look at the entire model-making scene, you will quickly see that the much-touted innovation in model making is far off. However, exceptions here also confirm the rule, and anyone who had the opportunity to look around at the last two trade fairs in Nuremberg suddenly found themselves in front of an aircraft model in which the word innovation came to life - a F4U-1D Corsair in scale 1: 15.

Not only does the scale go well beyond that of most aircraft modelers, but also the execution: built using the original building materials, every component of the original was modeled to scale. That alone is not necessarily innovative, because after all, there are always unique pieces of a similar kind on a small scale.

But if you then announce that you want to produce this masterpiece of model-making in a small series, then the term innovation is absolutely appropriate. The difficulties encountered in such an undertaking are hard to imagine. They are just as inconceivable as the manual skills of the man who built the prototype: Guillermo Rojas Bazàn.

As a young boy in Argentina, Bazàn built airplane models that later became so good that he tried to make a living from them. Argentina is not exactly the place to make money with this hobby, and Bazan decided to emigrate to the United States with his family. Armed with a tourist visa, he lived in America and built models for an agent who took advantage of his situation.

This is where Gary Kohs from Fine Art Models comes in - almost ready for script - who was looking for a capable model builder for aircraft and came across the name Bazàn. It took a long time before he could find the father of those outstanding models that had already caused a sensation among enthusiasts.

Gary Kohs brought Guillermo Rojas Bazàn and his family to Michigan, provided them with proper papers, and with his help began to realize the dream he always wanted to achieve: producing state-of-the-art models in a small series so that they are still affordable even for less wealthy aircraft fans.

The requirements for a small series are naturally completely different than for a one-off production. While you can fit each component in place for a one-off production and then continue working, complex devices and machines are required for a small series. All individual parts must be made in such a way that they can be built into a model without reworking.

It took over a year for Fine Art Models to solve these problems. After solving the technical requirements, another problem arose. The small series had to be assembled by model builders by hand - only where do you get these people from?

For ships manufactured in a similar manner, Fine Art Models had given up all their efforts years ago to set up production in the USA. Instead, a production facility had been set up in Riga. In the case of the Corsair, the necessary specialists were finally found in Kiev, Russia.

The first of 14 Corsair models are scheduled to be completed soon. In addition to the Corsair, a small series of Niewport 11 is already being made. The first series model was presented in Nuremberg. This model is also a true masterpiece, and the only difference between the model and the original is its size. For example, all six types of wood used in the construction of the original (continues below)

Translation of page 2:

[Caption] The powerful Hamilton standard propeller of the Corsair

[Caption] The wings can be folded

[Caption] In the shell: Corsair fuselage center piece

[Caption] Open air: all cowlings can be removed

[Caption] A dream in metal - the Corsair from Fine Art Models

[Caption] The chassis is also an exact replica

(continues from above) were also used to build the corresponding model parts. The Corsair was created according to the same philosophy. Here too, almost exclusively the materials used in the original were used to build the model.

The detailing is unique and cannot be surpassed, as all components of the original have been reproduced. In many cases, even at 1:15 scale, this is anything but easy. Models of these superlatives naturally also have their price. However, anyone who knows the lofty sums that have to be paid for one-off items by hand will almost regard a price of DM 12,500 for a Corsair (continues below)

Translation of page 3: